Automation and AI: Reshaping Modern Supply Chains

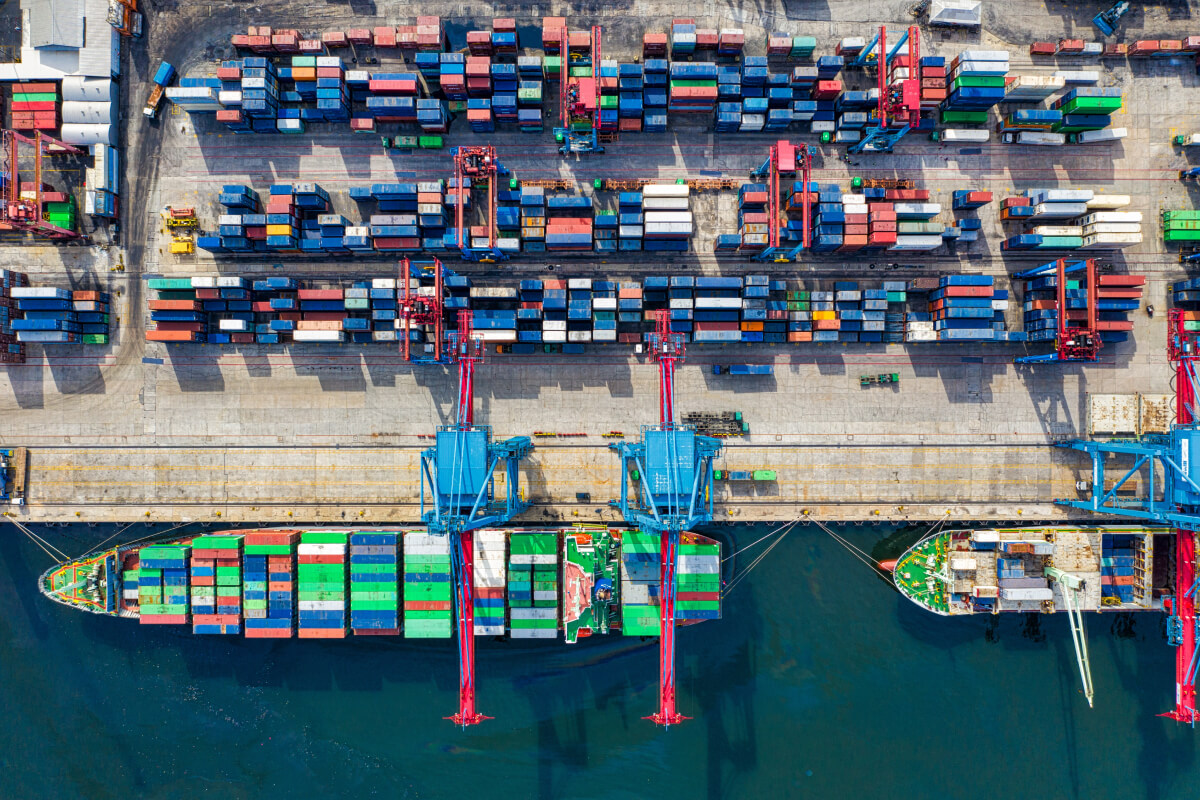

The combination of digitization and artificial intelligence (AI) has played a crucial role in redesigning contemporary supply chains in today’s quickly changing corporate environment. Businesses now have a wealth of opportunity to improve productivity, create better customer experiences, and streamline operations thanks to the disruptive interplay between technology and logistics. In this in-depth post, we will examine the applications, advantages, difficulties, and potential futures of artificial intelligence and automation in supply chains.

The shift in Supply Chains

Since their inception, supply chains have advanced significantly, changing from straightforward networks to intricate global ecosystems. The advent of automation and AI has been a game-changer, enabling firms to respond to the rapidly shifting market demands with previously unheard-of agility.

The Role of Automation

Robots and automated warehouses

The employment of robotics and automated warehouses is one of the supply chain automation’s most obvious features. Robots are used in these intelligent warehouses to carry out operations like picking, packing, and delivering items, greatly minimizing errors and human interaction.

Inventory Management

By enabling real-time tracking, assuring ideal stock levels, and automating replenishment procedures, inventory management automation simplifies the process. By reducing overstock and stockouts, this generates significant cost savings.

Order Processing

By quickly creating invoices, scheduling deliveries, and confirming orders, order processing automation streamlines the order processing process. This improves efficiency and order accuracy, raising customer happiness while simultaneously increasing efficiency.

The Power of Artificial Intelligence

Demand Forecasting and Predictive Analytics

With the use of past data analysis and industry trends, artificial intelligence can accurately forecast demand. This gives companies the ability to proactively change their production and inventory levels.

Route Improvement

AI algorithms improve delivery route planning, cutting down on expenses and environmental effect associated with transportation. This is accomplished by taking into account variables including traffic, the environment, and delivery windows.

Maintenance and Quality Assurance

AI-powered algorithms continuously check the quality of products, looking for flaws and irregularities. Additionally, by planning maintenance as needed, predictive maintenance algorithms can avoid expensive equipment breakdowns.

Benefits of Automation and AI

- Automation and AI significantly lower costs across the supply chain by lowering manual labor, minimizing errors, and optimizing procedures.

- In order to reduce the possibility of errors and delays, enhanced accuracy automation ensures a better level of accuracy in processes like order processing and inventory management.

- The total customer experience is improved by quicker deliveries, fewer order errors, and proactive communication powered by AI, which encourages loyalty and favorable ratings.

- A more sustainable and environmentally friendly supply chain ecosystem benefits from effective route planning and decreased waste as a result of better inventory management.

Future Possibilities

With automation and AI, supply chains will be even more innovative and integrated in the future.

Incorporating blockchain and IoT

By combining AI, the Internet of Things (IoT), and blockchain technology, fraud and errors can be decreased thanks to end-to-end visibility and transparency.

Chain of Supply Resilience

In order to make the supply chain more resilient to disturbances like pandemics or natural catastrophes, automation and AI will be essential.

Conclusion

A new era for supply chains has arrived thanks to automation and AI, elevating efficiency, precision, and adaptability to the fore. Businesses who adopt these technologies will succeed in the contemporary business environment.