Driving Efficiency and Innovation: 3D Printing in Automotive Manufacturing

The automotive industry is undergoing a remarkable transformation thanks to the disruptive power of 3D printing. This groundbreaking technology is reshaping traditional manufacturing processes and driving efficiency, innovation, and sustainability like never before.

Efficiency Boost: Streamlined Production

Gone are the days of complex tooling and assembly lines. 3D printing has revolutionized production processes by enabling rapid and cost-effective manufacturing of intricate parts. Unlike traditional methods with long lead times and high costs, 3D printing accelerates the development of new vehicle models while offering enhanced customization options.

Design Freedom: Pushing Innovation

With 3D printing, automotive designers enjoy unparalleled freedom. They can now bring to life complex geometries that were once deemed impossible or too costly to produce. From lightweight components to intricate interior features, 3D printing allows designers to push boundaries, resulting in aesthetically pleasing vehicles with improved performance and safety.

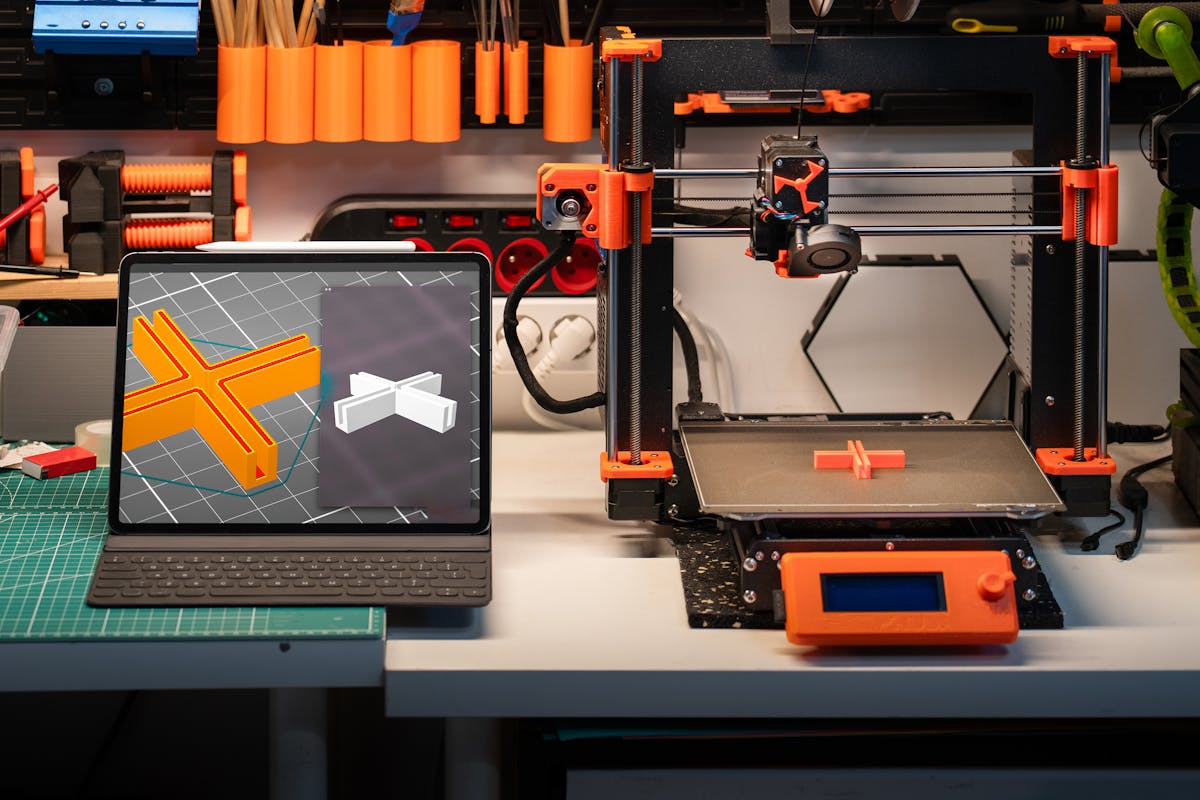

Rapid Prototyping: Speedy Iteration

Prototyping is a pivotal stage in automotive product development. Traditionally, it involved costly and time-consuming processes. However, 3D printing has revolutionized this phase, enabling rapid and cost-effective production of prototypes. Manufacturers can now iterate quickly, refining designs with ease, thus reducing time-to-market and staying ahead of the competition.

Sustainable Manufacturing: Eco-Friendly Approach

In today’s eco-conscious world, sustainability is paramount. 3D printing promotes sustainability in automotive manufacturing by minimizing material waste and carbon emissions. Unlike traditional methods that generate significant waste, 3D printing produces minimal waste as it utilizes only the material required for each component. Moreover, additive manufacturing techniques can incorporate recycled materials, further reducing environmental impact.

Customization Power: Tailored Solutions

Consumer demand for customization is at an all-time high. 3D printing empowers manufacturers to meet this demand by offering tailored solutions. Whether it’s personalized interior features or bespoke vehicle components, 3D printing allows for unprecedented levels of customization, enhancing the customer experience and fostering brand loyalty.

Conclusion: A New Era Unfolds

The impact of 3D printing on the automotive industry is undeniable. It is revolutionizing manufacturing processes, driving efficiency, innovation, and sustainability. As the technology continues to evolve, we can anticipate even greater advancements in automotive manufacturing, paving the way for a future defined by innovation, efficiency, and sustainability.

In essence, 3D printing is transforming the automotive industry, offering manufacturers new opportunities to innovate, streamline production, and meet the evolving needs of consumers—all while reducing environmental impact. As this technology matures, its potential to revolutionize the automotive industry knows no bounds.