The Impact of Generative AI on the Semiconductor Industry

Today, we’re looking at how generative AI could change the semiconductor industry. This technology could improve how things are done, offering new ways to design semiconductors and make them more efficiently. It might predict when machines need maintenance and help make better-quality products. This AI could revolutionize how semiconductors are made, making processes more precise and innovative. As companies start using AI more, they open the door to better designs, smoother operations, and more advanced technology, pushing semiconductor manufacturing into a new era of possibilities.

Utilizations of generative AI within the semiconductor sector.

1. Design Optimization

Generative AI can transform semiconductor design by generating fresh ideas, predicting how designs will perform, and finding the best configurations. This speeds up designing, making it faster to create chips that work better. By using AI to improve designs and simulate their performance, semiconductor companies can produce chips that meet the high demands of today’s technology. This helps them stay competitive and innovative in the industry. AI’s ability to optimize designs ensures that chips are not only efficient but also reliable, meeting the needs of various applications from smartphones to advanced computing systems. Thus, AI is pivotal in driving efficiency and performance improvements in semiconductor manufacturing.

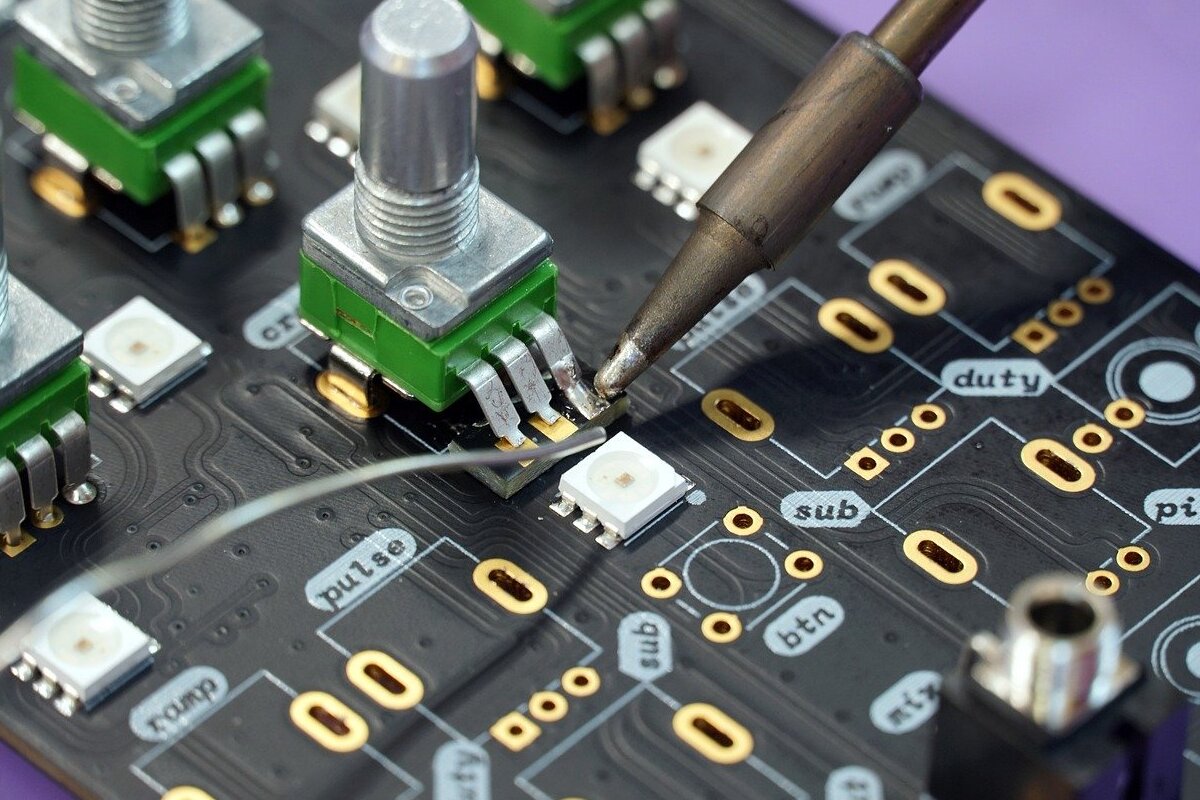

2. Process Improvement

Generative AI algorithms play a critical role in the semiconductor industry by analyzing extensive manufacturing data to detect patterns and refine production processes. By processing large datasets, AI identifies opportunities to enhance yield rates, minimize defects, and boost overall efficiency in semiconductor manufacturing. This optimization is crucial for meeting stringent quality standards and increasing production output while reducing operational costs. AI-driven insights enable semiconductor companies to predict and prevent potential issues before they impact production, ensuring smoother operations and consistent product quality. AI’s ability to continuously learn and adapt from data enables ongoing improvements in manufacturing processes, fostering innovation and competitiveness in the industry. Ultimately, AI’s application in semiconductor fabrication marks a significant advancement towards more efficient, reliable, and scalable production methods that meet the evolving demands of global markets.

3. Predict Maintenance Failure

AI-powered analytics are transforming semiconductor manufacturing by predicting equipment failures and maintenance requirements. By continuously monitoring equipment performance in real-time, AI identifies anomalies and potential issues before they lead to downtime. This proactive approach ensures uninterrupted production and minimizes disruptions in semiconductor fabrication processes. Predicting maintenance needs also optimizes scheduling, allowing companies to perform maintenance tasks at optimal times, thereby extending equipment lifespan and reducing overall maintenance costs. By leveraging AI’s predictive capabilities, semiconductor plants can enhance operational efficiency, improve resource utilization, and maintain high levels of production reliability. This proactive maintenance strategy not only boosts productivity but also enhances product quality assurance by ensuring that manufacturing equipment operates at peak performance levels consistently. Thus, AI-driven analytics are pivotal in transforming how semiconductor manufacturers manage equipment reliability and operational continuity.

4. Quality Assurance

Generative AI is revolutionizing quality control in the semiconductor industry by inspecting components with unparalleled accuracy. Using advanced algorithms, AI can identify defects and anomalies that are often imperceptible to human eyes, ensuring that only flawless products meet market standards. This capability not only enhances the reliability and performance of semiconductor devices but also reduces the risk of defective products reaching consumers. By automating the inspection process, AI accelerates quality assurance procedures, allowing manufacturers to maintain high production standards while increasing throughput. This transformative approach not only improves product reliability but also boosts customer confidence in semiconductor brands, reinforcing their reputation for delivering superior quality components. Embracing generative AI for quality control purposes enables semiconductor companies to uphold stringent industry standards and meet the growing demands for reliable, high-performance electronic devices in various applications.

5. Innovation and Research

AI can transform semiconductor research and development by expediting exploration into new materials, structures, and processes. By analyzing vast datasets and running simulations, AI accelerates the discovery of innovative semiconductor technologies. This includes developing materials with enhanced properties like conductivity or durability, optimizing transistor designs for better performance, and exploring new fabrication techniques to increase efficiency.

AI-driven R&D reduces trial and error cycles, enabling researchers to focus on promising avenues with higher success probabilities. This proactive approach fosters breakthroughs in semiconductor innovation, ranging from more energy-efficient chips to advanced semiconductor materials suitable for emerging technologies like artificial intelligence and Internet of Things (IoT) devices.

AI enhances collaboration by facilitating data sharing and analysis across research teams globally. This collaborative environment promotes knowledge exchange and accelerates the pace of innovation in the semiconductor industry. By leveraging AI’s capabilities, semiconductor companies can stay at the forefront of technological advancements, driving continuous improvements and maintaining competitive advantages in a rapidly evolving market.

6. Supply Chain Optimization

AI plays a pivotal role in semiconductor supply chain management by utilizing predictive analytics to forecast demand accurately, optimize inventory levels, and anticipate potential risks or disruptions. By analyzing historical data and market trends, AI enables companies to adjust production schedules and procurement strategies proactively. This ensures that semiconductor firms can meet customer demands efficiently while minimizing excess inventory and associated carrying costs. Additionally, AI’s real-time monitoring capabilities help identify supply chain vulnerabilities and enable swift mitigation measures, ensuring uninterrupted production and delivery. By integrating AI-driven insights into supply chain operations, semiconductor companies enhance operational efficiency, reduce logistics expenses, and maintain competitiveness in dynamic global markets.

Summary

In conclusion generative AI represents a transformative force in the semiconductor industry, poised to revolutionize operations across design, manufacturing, and supply chain management. By fostering innovation through accelerated research and development cycles, AI enables the discovery of novel materials and processes critical for next-generation semiconductor technologies. It enhances operational efficiency by optimizing production processes, predicting maintenance needs, and improving quality control with unprecedented accuracy. These advancements not only streamline operations but also elevate product reliability and performance, meeting the demands of modern technology applications.

The AI driven insights into supply chain management ensure efficient logistics and mitigate risks, safeguarding continuity in semiconductor production. As semiconductor companies embrace AI technologies, they gain a competitive edge through enhanced agility and responsiveness in a rapidly evolving market landscape. Ultimately, generative AI reshapes the semiconductor industry by empowering companies to innovate faster, operate more efficiently, and deliver superior products that drive technological progress in the digital era.